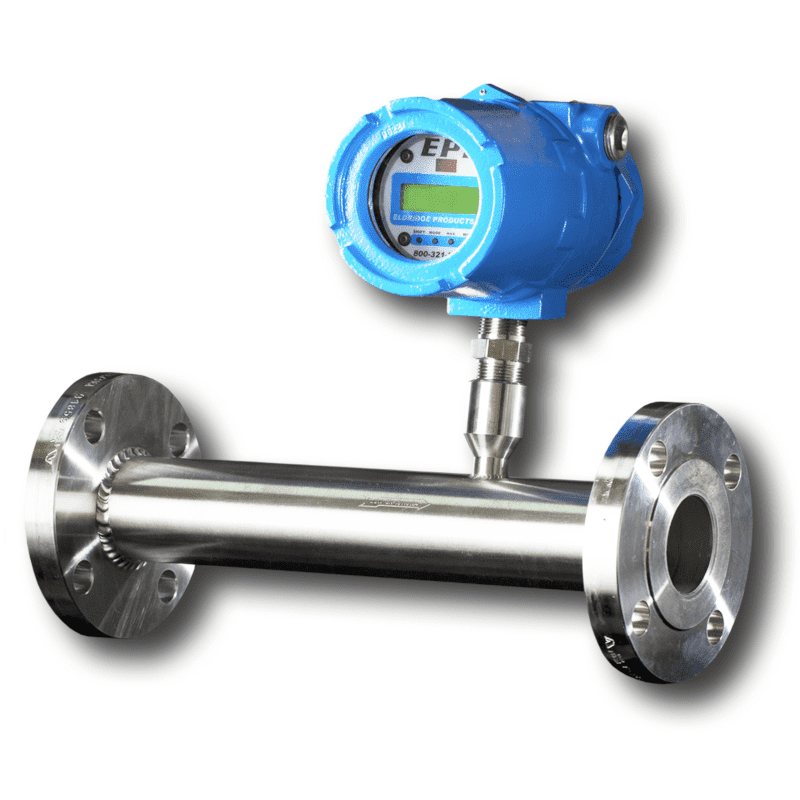

A thermal mass flow meter measures gas movement in different processes and offers different advantages like low maintenance, repeatability, and a wide operating flow range. This instrument is beneficial in many industrial processes. If you own an industrial plant, a thermal mass flow meter is an important tool you need to have.

A thermal mass flow meter is a precision tool that directly measures gas mass flow for compressed, industrial, and various gases. This instrument is used in different industrial applications, including:

- Carbon dioxide (for beverage production)

- Compressed air

- Bio-gas and air measurement (Wastewater plant)

- Argon (for steel production)

- Natural gas (for boiler feed and burners)

This precision instrument measures the movement of gas based on a principle called convective heat transfer. The meter does this by using heat to measure the flow. It will introduce heat into a moving stream and measure how well the heat dissipates using a temperature sensor. If you would like to know more about the working principle of this tool, read this article.

So, what are the approaches of this tool, and what are some of the advantages, and benefits to industries? Let’s discuss this.

How Does Thermal Mass Flow Meter Work?

As already mentioned, the thermal mass gas meter works using heat. But, what are some of the approaches or ways it does so? Here are two key approaches that it follows:

Constant Current Approach

This is a popular concept that this precision instrument follows. A thermal mass flow meter that follows this method uses heated sensors that sense the temperature of the moving stream. The energy from the heated sensor is kept constant. The flow is calculated as a function of the difference between the flow stream and the temperature of the heated sensor.

Constant Temperature Approach

Another approach is known as the constant temperature differential meter. This method uses two different temperature sensors: a heated sensor and one that measures the gas temperature. The flow rate is calculated based on the amount of energy or power (in kilowatts) needed to regulate a constant temperature between both the heated sensor and the temperature measuring one.

Both approaches are based on the thermal mass flow meter characteristics which explain how heat from the sensors measures gas movement.

Advantages of Thermal Mass Flow Meter

The following are some of the advantages of this precision instrument:

- Thermal meters do not come with moving parts. As a result, it is easy to maintain and can serve different purposes in demanding application areas.

- This instrument doesn’t calculate volumetric flow but instead calculates the mass movement of gas. It doesn’t need pressure or temperature correction, so you don’t have to buy and install extra equipment that improves the accuracy of such properties.

- A thermal mass meter provides repeatability and accurate measurement over a broad range of flow rates.

- This instrument can accurately measure air movement in large pipes.

Benefits of the Thermal Mass Flow Meter to Industries

The following are some of the benefits of this tool to different industries, including pharmaceutical companies, steel production, and beverage production plants:

It Maximizes Product Consistency

One of the key benefits the industry will enjoy from this tool is that it improves product consistency. For example, in pharmaceutical industries, during the coating and tablet processing, airflow can move the coating to the tablets. Any fluctuations in airflow can affect the coating thickness and make it uneven or inconsistent. This tool will avert this fluctuation and improve the coating consistency.

It Measures and Regulates Gas Usage

Many industries that employ the use of gases like oxygen, carbon dioxide (CO2), and nitrogen will want to measure the consumption of the gases. This instrument can monitor the usage of the gases and identify any abnormal uses such as a production problem or gas leak.

It Can Reduce Industrial Waste

In many industries, variation causes waste of materials. A high-precision meter is an important tool that helps to reduce variation in excess gas consumption. A short response time and high sensitivity of this instrument provide the necessary control for this. By quickly identifying waste, your engineers can control excess consumption and improve by-product yield.

It Reduces Costs

Having a thermal mass flow meter is cost-effective. Although the initial cost of purchasing and installing this equipment is on the high side, in the long run your industry will have saved enough money for maintenance and other miscellaneous items.

It is vital for you to think about the ROI of this instrument. Some of the uses of this tool include:

- Finding leaks and inefficiencies in a gas or air distribution system

- Accurately measuring the flow required to attain maximum industrial quality standards.

If you are constantly dealing with expensive materials, you need this precision instrument to avoid errors and improve the quality of your products.

Also, unlike other measurement tools, a thermal flow meter doesn’t require external devices to operate efficiently. You only need to purchase and install it and it will do all the wonders for you.

Also Read: Tips To Make Your Offshore Winds Project Successful

Conclusion

A thermal mass flow meter is a vital industrial precision tool that can serve different purposes for different industries. It is cost-effective and can last for a long time if well-maintained.